Modern infrastructure relies on robust pipelines to transport vital resources such as water, oil, and gas efficiently and safely. As demands on pipeline systems increase and environments grow more challenging, the materials selected for their construction must meet stringent standards for durability, environmental compliance, and long-term performance. Today’s pipeline projects leverage cutting-edge materials science to address corrosion, fatigue, and ecological challenges, ensuring that networks remain reliable and future-ready. Companies like Cruco Mill & Industrial Supply North Carolina are at the forefront of delivering advanced materials and solutions tailored to the evolving requirements of the industry.

The past decade has seen transformational changes in the approaches to pipeline materials. Enhanced composites, sensor-embedded smart layers, and coatings developed with nanotechnology are just a few examples of the strides being made. These innovations are designed to help infrastructure professionals meet regulatory requirements, enhance operational safety, and mitigate the risk of costly repairs or environmental issues in the future.

With fuel transitions, climate adaptation, and regulatory pressures shaping tomorrow’s infrastructure, choosing the right pipeline materials is no longer only about cost or strength. It’s a strategic decision that safeguards community resources and a company’s reputation. This article examines the latest developments in pipeline materials, highlighting key features, practical benefits, and real-world applications.

As you look to modernize or expand pipeline networks, understanding the underlying technologies will help you make informed decisions and achieve sustainable, high-performance results for your projects.

Reinforced Thermoplastic Pipes

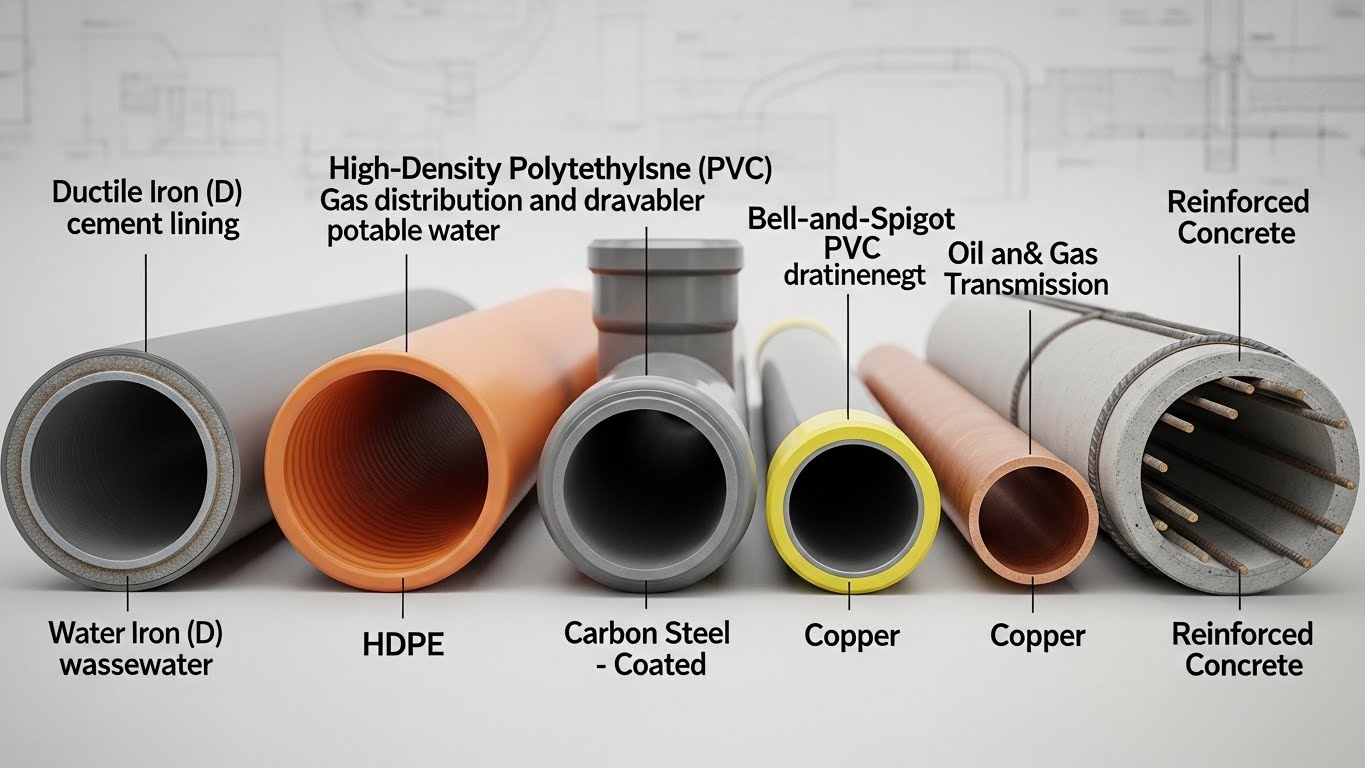

Reinforced Thermoplastic Pipes (RTPs) are increasingly favored in critical infrastructure projects due to their corrosion-free operation and ease of handling. Unlike traditional steel pipes, RTPs require no internal coatings, drastically lowering the risk of contamination and buildup within the pipeline. Their lightweight structure promotes faster installation, further reducing labor costs and emissions from heavy equipment.

These pipes are also highly resistant to fatigue, making them suitable for environments subject to regular vibration and shifting, such as offshore oil platforms or regions with variable temperatures. Operators from the Middle East to the North Sea have adopted RTPs for applications like water and gas injection lines, reporting significant decreases in unplanned maintenance and system downtime. According to the U.S. Department of Energy’s HyBlend initiative, the use of advanced pipe materials is crucial for enhancing reliability and reducing lifecycle costs in energy distribution.

Nanotechnology-Enhanced Coatings

Protecting pipelines from corrosion and environmental damage is vital for safe operation and longevity. Recent advancements in nanocomposite coatings incorporate nanoparticles, such as graphene and carbon nanotubes, into traditional protective layers. These nano-enhanced coatings exhibit exceptional barrier effects, higher mechanical strength, and the ability to “self-heal” minor scratches or breaches.

Pipeline operators report enhanced adhesion and resistance to UV, abrasion, and extreme temperatures. Field trials with nano-epoxy coatings have demonstrated a 30% increase in durability compared to legacy coatings, resulting in longer maintenance intervals and lower repair costs. Such coatings represent a crucial step forward for both new builds and legacy infrastructure, especially as environmental regulations continue to tighten globally.

Innovative Materials for Real-Time Monitoring

Innovative smart materials, embedded with advanced sensors, are transforming pipeline maintenance from a reactive to a proactive approach. These systems commonly integrate fiber optic cables for distributed sensing, piezoelectric sensors for stress monitoring, and shape memory alloys that change physical states in response to strain or temperature fluctuations, relaying early warning signals.

Real-time health monitoring allows operators to detect leaks, stress, and thermal anomalies before they escalate into failures. Predictive alerts and automated reporting reduce reliance on manual inspections, mitigating environmental, financial, and reputational risks associated with undetected leaks. For example, tests of clever fiber-optic liners have proven successful in detecting small leaks more quickly than standard external monitoring approaches, enabling swift intervention.

High-Performance Alloys

High-Performance Alloys (HPAs), such as duplex stainless steels, Inconel, and Hastelloy, are increasingly used to overcome limitations associated with traditional carbon steels—especially in aggressive environments like deep-sea or “sour gas” applications. These alloys provide excellent corrosion resistance and maintain integrity at high temperatures, which is critical in the energy sector pipelines. HPAs offer a higher strength-to-weight ratio, allowing engineers to design thinner, lighter pipelines without sacrificing reliability, thereby decreasing both material and transportation costs.

Real-world adoption of HPAs can be seen in subsea oil lines exposed to saltwater and corrosive gases, areas where material failure would have catastrophic consequences. Research published by ScienceDirect highlights the role of alloys in extending the lifespan of critical pipeline components under extreme pressure and temperature conditions.

Composite Materials

Composite materials, such as fiberglass-reinforced polymers (FRP), are providing an attractive alternative to metals for both pipeline construction and repair. These materials deliver superior corrosion resistance and can be manufactured with customized mechanical properties to suit specific applications. Composites weigh less than traditional steel, resulting in substantial savings in shipping, handling, and installation costs. Additionally, their immunity to many forms of environmental degradation extends the life of both new and rehabilitated pipeline sections.

Composite wraps or sleeves can be applied over existing pipelines to remediate issues like external corrosion, dents, or gouges. This extends the operating lifespan of the asset while minimizing disruption to operations and eliminating the need for costly excavations or replacements.

Sustainable Innovations

Sustainability is now a fundamental expectation in pipeline development. Companies are turning to bio-based epoxy resins as alternatives to traditional petrochemical-based products to minimize environmental impact. These resins reduce emissions of volatile organic compounds (VOCs) and help companies comply with regulatory shifts that demand greener construction practices.

UV-cured lining systems are another sustainable breakthrough, eliminating the use of harmful solvents while cutting field-related installation emissions by about 30%. Such technologies can achieve service lives surpassing 75 years, supporting both environmental and economic objectives. Forward-thinking organizations continually seek new ways to reduce their carbon footprints and build pipelines that will remain safe and efficient for generations to come.

Conclusion

The landscape of pipeline materials is evolving rapidly, responding to the challenges of safety, performance, and sustainability in equal measure. Reinforced thermoplastic pipes, nanotechnology coatings, innovative sensor-based solutions, advanced alloys, and sustainable composites are setting new standards in infrastructure resilience. For engineers, operators, and planners, staying informed about these innovations is crucial to delivering projects that are efficient, reliable, and environmentally sound