In modern furniture manufacturing, the appearance and durability of edges determine both first impressions and product longevity. The quest for ultra-smooth, flawless edges drives the industry to refine its methods and embrace technology continually. Edge enhancements extend well beyond mere surface appeal, safeguarding core materials, promoting product longevity, and elevating professional standards. Whether you’re a large-scale manufacturer or a boutique workshop, integrating advanced processes like edgebanding chemicals and sophisticated machinery is now a fundamental industry norm.

With shifting trends and rising demand for sustainable, seamless designs, mastering edge-finishing processes has become a must for companies that value both aesthetics and resilience. It’s not only about hiding panel cores—protecting against heat, moisture, and daily wear is equally critical. Innovation in adhesives, application techniques, and edge banding materials means that now, more than ever, the final touch truly makes a piece stand out in competitive furniture markets.

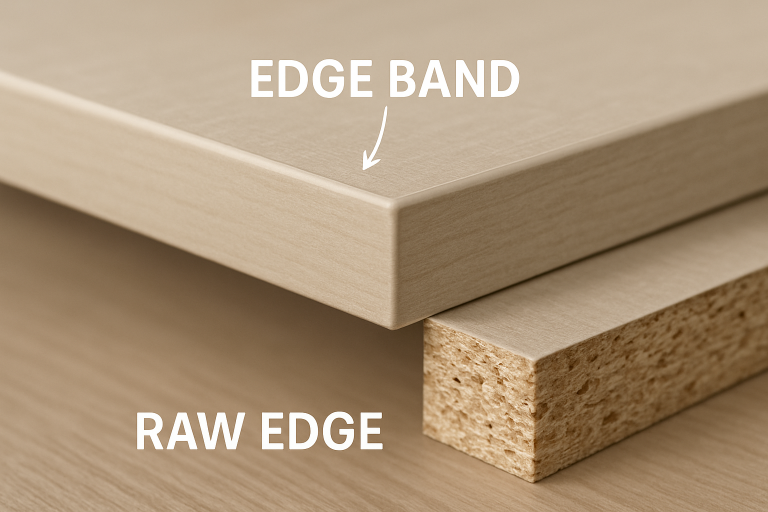

The Importance of Edge Banding

Edge banding is the technique of applying a protective and decorative strip to the raw edges of composite wood panels. This essential finishing touch serves several purposes: visually transforming cut board edges, reinforcing weak points, and protecting the core from damage caused by daily handling or environmental moisture. Edge banding, whether applied with specialized adhesives or modern laser fusion, creates furniture that not only looks sleek and contemporary but also endures everyday use.

The evolution of edge banding means customers now expect both visual perfection and superior resilience in finished products. In both commercial and residential furniture, robust edge banding enhances safety by masking sharp edges. It plays a vital role in maintaining hygiene by preventing water and debris from seeping into the core. Brands that execute this step flawlessly command higher prices and customer trust, positioning themselves as leaders in craftsmanship.

Advanced Edgebanding Technologies

Technological advancements have redefined what furniture makers can achieve with edge banding. Laser edgebanding is at the forefront, offering perfectly seamless joints by melting the adhesive directly into the panel and edge band for an invisible, strong bond. This state-of-the-art approach produces a continuous look, free from visible glue lines, making it popular for luxury and high-gloss panels.

Hot-melt edgebanding remains prevalent for its rapid application and reliable results. Here, thermal adhesives such as EVA (ethylene vinyl acetate) or more advanced PUR (polyurethane reactive) hot melts are applied to the banding material, ensuring a rapid set and robust adhesion. Whether using laser or hot-melt systems, upgrading to the latest edge-finishing solutions directly translates into less maintenance, reduced labor, and repeatable, superior output.

Sanding Techniques for Smooth Edges

A perfectly finished edge relies on proper preparation, making sanding an indispensable part of the process. Effective sanding eliminates manufacturing marks, irregularities, and sharp corners that could hinder the application of edge banding or finishing materials. It starts with a coarse grit to level out imperfections and moves to progressively finer grits for silky-smooth results:

- Coarse Grit (40-60): Quickly removes machine marks or aggressively smoothed surfaces.

- Medium Grit (80-120): Bridges the transition from rough to finer smoothing, prepping for adhesive compatibility.

- Fine Grit (150-220+): Delivers the final, tactile smoothness needed for flawless paint, stain, or laminate finishes.

Sanding not only sets the stage for professional-looking edges but also enhances durability by ensuring adhesives bond more securely with the underlying panel.

Automation in Edge Finishing

The demand for precision and repeatability has led to the widespread adoption of automated edge banding machines. These systems handle every aspect—from automatic feeding and glue application to trimming, buffing, and surface cleaning—eliminating manual errors and inconsistencies. Advanced examples, such as those from HOMAG, pair software-guided controls with multi-stage processing in a single pass, dramatically increasing productivity in large-scale operations.

Automation isn’t just about speed; it enables greater design flexibility, reduces material waste, and guarantees consistently top-tier finishes on a commercial scale. As consumer standards continue to climb, machine-driven edge finishing has become vital for competitive furniture manufacturing.

Choosing the Right Materials

Material selection dramatically influences the final look, feel, and function of edge banding. The most commonly utilized materials include:

- PVC: Recognized for its resilience, broad color range, and texture options.

- ABS: A sustainable, recyclable plastic that combines strength with environmental responsibility.

- Wood Veneer: Offers a premium, natural finish that can be stained or clear-coated to match the primary surface.

Choosing among them depends on usage conditions, client preferences, budget, and environmental impact targets—each material lending distinct advantages to finished furniture.

Quality Control Measures

Ensuring a flawless edge finish requires rigorous oversight at every step. Key measures include regular adhesive bond tests, meticulous inspection for alignment and trim consistency, and verification against set quality standards. Investing in precision machinery further reduces human variability and enhances batch-to-batch quality, resulting in near-perfect edge applications across product lines.

Many leading manufacturers now integrate digital measurement and tracking systems into their production environments, ensuring every piece meets expectations before leaving the floor. Quality commitment builds brand reputation, fosters customer loyalty, and minimizes costly returns or repairs.

Conclusion

Professional-grade furniture edges are the product of innovation, precision, and a relentless pursuit of quality. Manufacturers who blend proven practices, advanced edge banding technologies, and stringent quality controls can deliver pieces that impress visually and endure over time. As the bar for customized, sustainable, and seamless furniture continues to rise, edge finishing will remain central to craftsmanship and commercial success.