Maintaining pipeline integrity is vital for safe, efficient transport of resources like water, oil, and gas. As urban populations and industrial demands grow, pipelines are more crucial than ever. Traditionally, repairs involved disruptive excavations causing neighborhood disruptions, downtime, and high costs. Today, technology provides less invasive options that protect pipelines with minimal disruption, safeguarding communities and assets. One foundational tool is understanding the pigging process for pipeline integrity—a critical method for cleaning, inspecting, and maintaining pipelines from within, minimizing operational interruptions. These advancements help organizations overcome geographic, financial, and environmental challenges with pipeline networks by limiting excavation and using high-tech monitoring. Innovations like non-intrusive inspections and real-time monitoring set new standards for pipeline safety, reliability, and sustainability. This allows operators to be more proactive, efficiently addressing aging systems and incidents.

Cured-In-Place Pipe (CIPP) Technology

CIPP is a trenchless rehabilitation solution revolutionizing pipeline repairs across water, sewage, and gas systems, and is quickly becoming the industry standard in urban infrastructure maintenance. In this process, a resin-saturated liner is inserted and cured within the existing pipe, creating a structurally sound new pipeline without the need for traditional excavation. Once in place, the liner hardens to form a seamless, jointless pipe within a pipe that can span damaged or corroded sections and restore system function for decades. This not only speeds up repairs but also minimizes environmental disruption, reduces neighborhood disturbances, and significantly lowers direct and indirect costs compared to pipe replacement. CIPP can address issues spanning pipes from 0.1 to nearly 3 meters in diameter, making it adaptable for both urban and remote settings. Additionally, the quick turnaround and minimal restoration required after installation support sustainability and reduce the project’s overall carbon footprint.

Robotic Non-Destructive Testing (NDT)

Robotic NDT combines advanced mobility with a suite of inspection sensors, providing a safer and more thorough approach to internal pipeline evaluations. Unlike traditional inspections that often require shutting down operations or entering hazardous environments, robotic crawlers navigate through “unpiggable” or hard-to-access lines. These robots excel at navigating bends, length, and changes in pipeline diameter, with capabilities that far exceed what manual inspection crews can achieve. Equipped with technologies such as ultrasonic, magnetic flux leakage, and visual sensors, these robots collect high-fidelity data in real-time, offering a comprehensive internal and external assessment. This enables the immediate analysis of corrosion, cracks, and defects, significantly enhancing predictive maintenance while reducing safety risks to human operators. By digitizing and automating the inspection process, companies can quickly spot vulnerabilities, prioritize repairs, and document pipeline conditions for regulatory compliance.

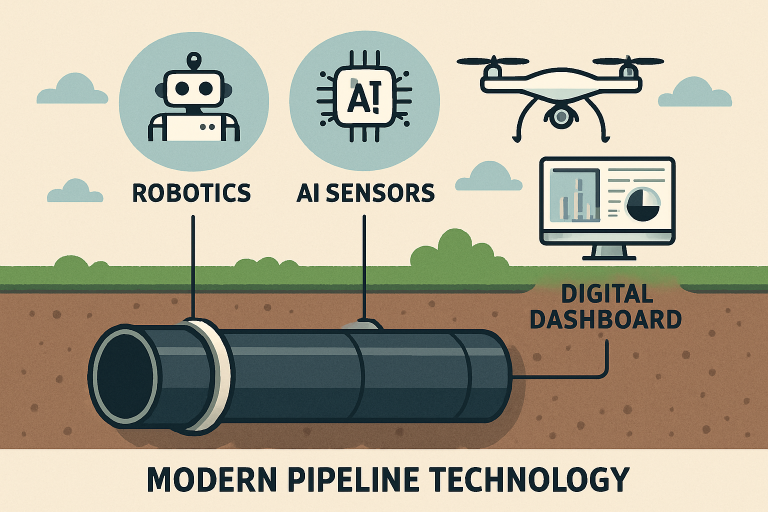

Integration of AI and IoT in Pipeline Monitoring

The digital transformation of pipeline maintenance hinges on the synergy between AI and IoT. Networks of smart sensors continuously gather data on pipeline conditions, flow rates, and environmental factors, creating a multidimensional dataset that surpasses the capabilities of manual monitoring methods. Advanced AI algorithms ingest this data to identify subtle anomalies, such as pressure drops or minute leaks, that periodic manual inspections might miss. This enables real-time predictive maintenance, allowing teams to address minor issues before they escalate into major failures. Virtual dashboards also make diagnostics and reporting accessible from anywhere at any time. Industry statistics indicate that AI-driven monitoring can reduce downtime by up to 20% and lower overall maintenance costs by 15%, solidifying its value as a core pillar of modern pipeline management. Over time, the learning capabilities of AI systems have improved fault prediction, making them increasingly reliable and cost-effective.

Autonomous Drones for Inspection

Autonomous drones equipped with multispectral cameras and LiDAR are revolutionizing the inspection of pipelines—especially those spanning challenging or remote terrain. These aerial platforms rapidly cover large distances and provide a comprehensive visual and thermal assessment, enabling early detection of surface anomalies, soil shifts, and vegetation encroachment. Drones can instantly identify leaks, overgrown vegetation obstructing access, physical threats like landslides, or signs of unauthorized construction near pipeline rights-of-way. The use of drones reduces reliance on ground teams and allows for the safe monitoring of pipeline sections that would otherwise pose significant logistical or safety challenges. Drones also facilitate seamless documentation and data sharing across maintenance teams for quicker decision-making. With accessible, up-to-date imagery and automated flight paths, the efficiency and effectiveness of routine inspections are vastly increased, reducing the risk of undetected issues.

Digital Twins and Predictive Maintenance

Digital twin technology offers a virtual, dynamic representation of physical pipelines, integrating real-time sensor data, historical maintenance logs, and operational simulations. This digital mirror enables engineers to monitor asset health, simulate stress tests, and visualize how altering operational variables may impact performance or integrity. With predictive analytics, organizations can transition from reactive responses to proactive interventions, reducing unplanned outages while extending the lifespan of their infrastructure. Accurate digital twins also simplify long-term asset planning and regulatory reporting by supplying consistent, traceable records throughout the infrastructure’s lifecycle. By leveraging digital twins, maintenance managers can proactively plan interventions, optimize resource allocation, and achieve cost savings, thereby ensuring pipeline longevity and maximizing resource utilization.

Conclusion

The future of pipeline infrastructure depends on embracing technological innovation to drive safer, more efficient, and environmentally responsible maintenance practices. Methods such as CIPP, robotic NDT, AI-powered monitoring, autonomous drone inspections, and digital twins are transforming pipeline management by integrating advanced analytics, automation, and sustainability into everyday operations. These pivotal advancements not only bolster operational safety and minimize downtime but also support a more sustainable approach by reducing disturbances and resource use. As the industry continues to evolve, staying informed about leading-edge developments will ensure robust and reliable pipelines for years to come, thereby safeguarding both public resources and business investments.