Introduction to 316 and 316L Stainless Steel

Stainless steel is recognized across various industries for its exceptional corrosion resistance, durability, and ability to maintain structural integrity in demanding environments. Among its many alloys, 316 and 316L stainless steel, available at https://www.specialtysteel.com/, are two of the most widely used, each featuring distinct properties that make them especially suited for specific applications. When determining which grade to use, understanding the differences between them can help avoid material failures and ensure long-term performance.

Both 316 and 316L belong to the austenitic family, which is prized for its non-magnetic properties and resistance to various forms of corrosion. While their similarities foster some overlap in industrial usage, the differences between these grades—especially regarding composition and performance—are pivotal to material selection.

The distinctions impact not only the steel’s performance under mechanical and environmental stresses but also dictate the ease of fabrication, suitability for welding, and compliance with regulatory requirements in certain sectors. Selecting the right type comes down to a close examination of the working environment, regulatory standards, and anticipated operating conditions. Given the widespread utilization of these stainless steels, a deeper understanding of their differences can help purchasers, fabricators, and engineers make informed decisions for both immediate and long-term requirements.

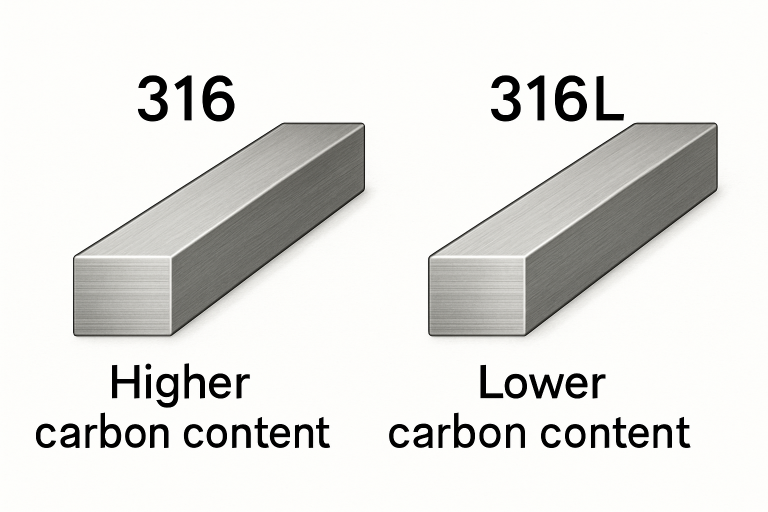

Chemical Composition Variations

The defining difference between 316 and 316L stainless steel is in their carbon content. Carbon plays a crucial role in determining hardness and machinability, but excessive amounts can compromise corrosion resistance during specific processes.

- 316 Stainless Steel: Contains up to 0.08% carbon, along with approximately 16-18% chromium, 10-14% nickel, and 2-3% molybdenum. The presence of molybdenum further enhances its resistance to chemical corrosion and pitting from chlorides.

- 316L Stainless Steel: Contains a maximum of 0.03% carbon. This minimal carbon reduces the risk of carbide precipitation during welding, thus preventing chromium depletion and maintaining optimal corrosion resistance around welds.

This subtle difference in carbon makes 316L better suited for critical welded structures, including those used in food and pharmaceutical processing, where stringent regulatory requirements for hygiene and corrosion resistance are in place.

Impact on Corrosion Resistance

Both grades are engineered to thrive in challenging and corrosive environments, notably those exposed to saltwater or harsh chemicals. The addition of molybdenum provides an extra layer of protection against localized corrosion, particularly in environments rich in chloride, such as those found in marine applications and chemical processing plants.

Where they diverge is in their respective performance after welding. The lower carbon content of 316L significantly reduces the risk of intergranular corrosion around welded areas—a form of attack that can compromise the integrity of stainless steel joints in traditional 316 alloys unless post-weld heat treatment is applied. As a result, 316L is often the material of choice for welded assemblies, process piping, and pressure vessels where corrosion resistance is crucial.

Mechanical Properties and Strength

Mechanical performance is another key consideration, especially for load-bearing or high-pressure environments. While the differences are slight, 316 stainless steel boasts higher tensile and yield strengths compared to its low-carbon counterpart, making it a logical choice for parts, fasteners, and components where strength is critical.

By contrast, the lower carbon level in 316L results in marginally reduced strength; however, this trade-off is usually acceptable—if not preferred—in applications that prioritize ductility, formability, or corrosion resistance over sheer physical strength. This makes 316L ideal for components that experience repeated thermal cycling or severe fabrication processes.

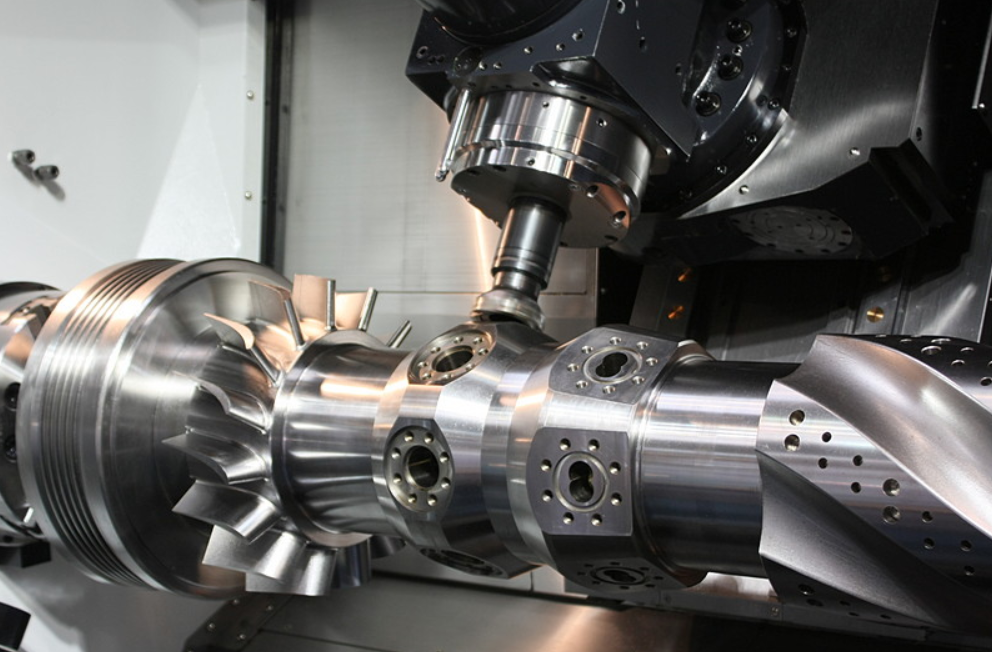

Weldability and Fabrication Considerations

Welding stainless steels can often lead to the formation of chromium carbides at grain boundaries, resulting in the loss of corrosion resistance, a phenomenon known as sensitization. Thanks to its reduced carbon content, 316L virtually eliminates this concern, allowing for welding without post-weld annealing—a key advantage in many manufacturing, marine, and construction settings.

Fabricators prefer 316L for complex assemblies and thick-walled structures, as it simplifies production, reduces material waste, and helps avoid costly failures during inspection and service. By contrast, standard 316 stainless steel may require additional steps to maintain optimal corrosion resistance after welding.

Applications in Various Industries

The selection between these two stainless steel grades depends greatly on their intended end-use. Their respective strengths lend themselves well to specific industry requirements:

- 316 Stainless Steel: Common in marine hardware, chemical processing equipment, medical instruments, and high-stress mechanical parts because of its higher strength and excellent resistance to sulfates, bromides, and acidic conditions.

- 316L Stainless Steel: Favored in food, beverage, and pharmaceutical processing, as well as water treatment, pulp and paper manufacturing, and decorative architectural features, where extensive welding is necessary, and cleanability is crucial.

Cost Implications

316L stainless steel is generally priced slightly higher than its counterpart due to the more stringent controls required to minimize carbon during production. For projects that involve minimal welding, this price premium may not be justified. However, the marginal cost increase is often a smart investment in applications where corrosion resistance after welding is non-negotiable and the cost of future repairs or replacement could be significant.

Purchasers should evaluate not just the upfront cost, but the lifecycle value these materials offer within their specific application environment.

Final Thoughts

316 and 316L stainless steel stand out as versatile and dependable alloys for hostile environments and demanding fabrication processes. The distinctions in carbon content and resulting performance after welding are what primarily differentiate the two. By pairing an understanding of industry standards, environmental conditions, and processing needs with these material properties, engineers and specifiers can confidently select the optimal grade for long-term success in their applications.