Italian cuisine is a masterpiece in itself, and pasta is one of its most beloved creations. Among the countless varieties, tortellini holds a special place for its delicate shape and rich fillings. Making these tiny pasta rings by hand can be labor-intensive, which is where the tortellinatrice comes in. This machine has revolutionized how tortellini are prepared, balancing tradition with innovation to meet modern demands.

The Origins of Tortellini and Its Tradition

Tortellini originated in the Emilia-Romagna region of Italy, where stories describe their shape as inspired by a goddess’s navel. Traditionally, families would gather around the kitchen table, rolling dough and shaping tortellini by hand. It was more than food; it was a ritual. Even today, tortellini is tied to Italian identity and is often enjoyed in broth or with creamy sauces.

What Is a Tortellinatrice?

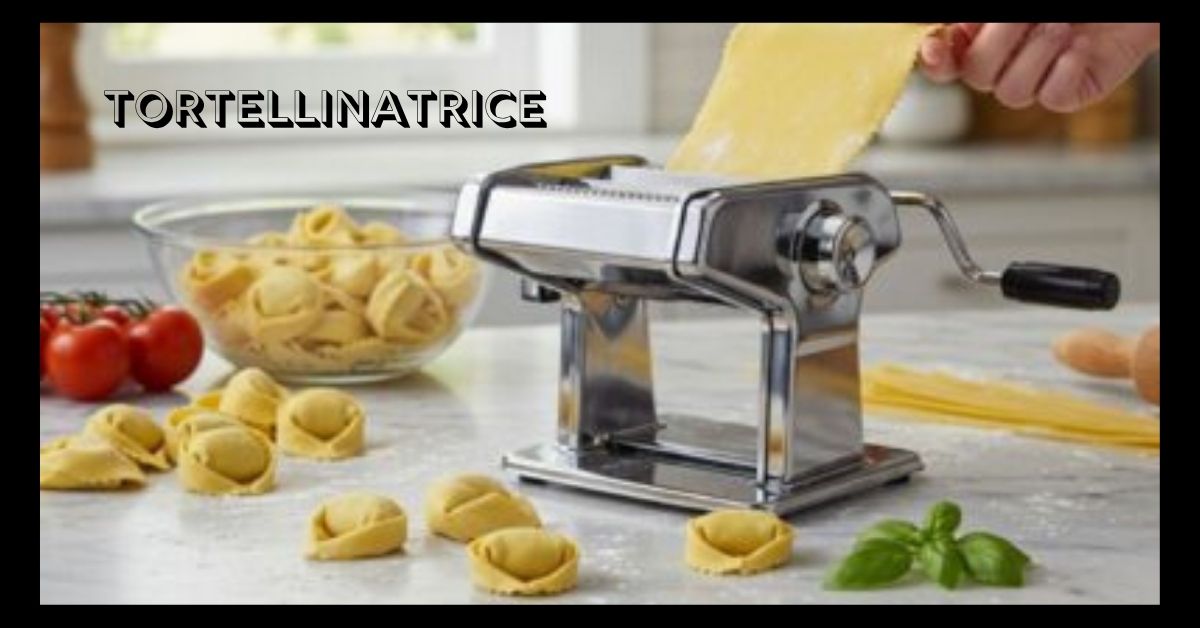

A tortellinatrice is a specialized pasta-making machine designed to shape and seal tortellini efficiently. Instead of spending hours folding each piece by hand, this machine automates the process without sacrificing quality. Depending on the model, it can be operated manually for small batches or run automatically for large-scale production.

How a Tortellinatrice Works

The working principle is simple but ingenious. Sheets of pasta dough are fed into the machine, followed by small deposits of filling. The tortellinatrice then cuts, folds, and seals the pasta into the iconic ring shape. This ensures uniformity, which is especially important in restaurants and factories where consistency matters.

Types of Tortellinatrice Machines

Like most kitchen equipment, tortellinatrice machines come in different designs to suit various needs. Some are compact and manual, perfect for households or small businesses, while others are industrial-scale machines capable of producing thousands of tortellini per hour. Each type caters to a different level of demand, from artisanal pasta shops to major food companies.

Manual Tortellinatrice for Home Use

For passionate home cooks, manual tortellinatrice machines are a dream. They allow individuals to enjoy the authentic process of making tortellini without spending endless hours shaping by hand. While they require some effort, they preserve the intimate feel of traditional cooking, making them a favorite for culinary enthusiasts.

Industrial Tortellinatrice for Large Production

In contrast, industrial tortellinatrice machines are engineered for speed and efficiency. Used in factories and large kitchens, these machines can produce massive quantities in a short time. Their precision and automation help maintain the delicate balance between preserving traditional shapes and meeting market demands.

Why Tortellinatrice Is Essential in Pasta Making

Without a tortellinatrice, producing large amounts of tortellini would be nearly impossible. The machine ensures every piece is uniform, filled properly, and sealed securely to prevent leakage during cooking. It saves time, reduces labor costs, and makes tortellini accessible to global markets while keeping the traditional recipe intact.

Benefits of Using a Tortellinatrice

The benefits go beyond just efficiency. A tortellinatrice maintains consistent quality, reduces waste, and increases output. It also allows chefs and producers to experiment with different fillings without worrying about uneven sealing. For businesses, the machine translates into higher productivity and customer satisfaction.

Step-by-Step Process of Making Tortellini with a Tortellinatrice

The process begins with preparing the pasta dough and filling. Once ready, the dough sheets are inserted into the machine while the filling is loaded into a hopper. The tortellinatrice then cuts the dough into shapes, folds them around the filling, and seals the edges. Within minutes, dozens of identical tortellini are ready to be cooked or packaged.

Materials and Design of Tortellinatrice Machines

Most tortellinatrice machines are made from stainless steel, ensuring durability and food safety. Their design balances practicality with precision, often featuring adjustable molds to customize the size of tortellini. High-end models may include digital controls, safety systems, and user-friendly interfaces for easier operation.

Maintenance and Cleaning Tips

Like any kitchen equipment, proper maintenance ensures longevity. A tortellinatrice should be cleaned immediately after use to prevent dough and filling from drying inside the machine. Regular lubrication of moving parts, inspection for wear, and careful handling of molds are essential practices to keep it running smoothly.

Common Mistakes to Avoid When Using a Tortellinatrice

Beginners often make simple mistakes, such as using dough that is too thick or overfilling the machine. Both can cause the tortellini to tear or leak during cooking. Another common error is skipping regular cleaning, which can shorten the machine’s lifespan. Learning to balance dough texture, filling quantity, and maintenance is key.

Buying Guide: How to Choose the Right Tortellinatrice

When choosing a tortellinatrice, consider your needs. Home cooks may prefer a manual version, while restaurants might need a semi-automatic machine. Industrial buyers should look for fully automated systems with customizable molds. Budget, space, and expected output are all factors that determine the right choice.

Tortellinatrice in Italian Culinary Culture

In Italy, the tortellinatrice is seen not as a replacement for tradition but as a continuation of it. Many pasta makers use the machine to keep up with demand while still following authentic recipes. For Italians, the soul of tortellini lies in the filling and dough quality, not necessarily in how it is shaped.

Innovation and Modern Technology in Tortellinatrice

Modern tortellinatrice machines now include smart features like automated filling controls, adjustable sealing pressure, and touchscreen operations. These innovations make the machines more versatile, energy-efficient, and user-friendly, further bridging the gap between artisanal craftsmanship and industrial production.

Comparing Handmade vs Machine-Made Tortellini

Handmade tortellini carries sentimental value and slight imperfections that highlight its authenticity. Machine-made tortellini, however, offers consistency and availability on a larger scale. Both methods have their place in the culinary world, with handmade versions often reserved for family gatherings and machine-made ones for restaurants and stores.

Future of Tortellinatrice in Global Pasta Industry

As global demand for Italian cuisine grows, tortellinatrice machines will play an even bigger role. With advancements in technology, these machines may become more affordable and accessible, allowing even small businesses to compete internationally. The fusion of tradition and innovation ensures tortellini will remain a global favorite.

Conclusion

The tortellinatrice is more than just a machine—it is a bridge between Italy’s rich culinary traditions and the modern world’s need for efficiency. By preserving the essence of tortellini while making production practical, it keeps this beloved dish alive for generations to come. Whether in a small kitchen or a large factory, the tortellinatrice ensures that the art of pasta-making never loses its charm.

FAQs

- Is tortellini always made with a tortellinatrice?

No, tortellini can still be made by hand, but the machine makes the process faster and more consistent. - Can I use a tortellinatrice at home?

Yes, manual versions are available for home cooks who want to enjoy authentic pasta-making. - How much does a tortellinatrice cost?

Prices vary widely, from affordable manual models for home use to expensive industrial machines. - Does machine-made tortellini taste different from handmade?

The taste depends more on the dough and filling than the machine. Both methods can produce delicious results. - What types of fillings can be used in a tortellinatrice?

The machine can handle a wide range of fillings, from meat and cheese to vegetarian and gourmet options.